Dry etching (ion plasma):

- RIE, DRIE

- FIB (Focus Ion Beam)

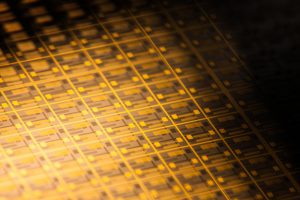

- Materials: Silicon (max 6 inches), Glass, Si3N4, LiNbO3,… (max 4 inches)

Wet etching:

- KOH, BHF

- Vapor HF Etching

Dry etching (ion plasma):

Wet etching:

In addition tosiliconetching, we have developed various deep etching processes for dielectric materials in a clean room:

| Engraved materials | Depth |

Verticality of the sides |

Roughness at the bottom of the engraving |

| Glass | Up to 200 µm | 70° to 100 µm | Ra < 500nm |

| Quartz | Up to 200 µm | 85° to 100 µm | Ra < 10nm |

| Lithium niobate | Up to 10 µm | 75° to 10 µm | Ra < 10nm |

Benefits:

– Collective etching of micrometric resolution patterns with depths of up to a hundred microns

–New features for your devices

–Improved performance of your devices

Different applications are targeted:

– Structuring of microfluidic channels in biocompatible materials (Glass, etc.)

– Manufacture of optical waveguides in electro-optical materials (Lithium Niobate …)

– Engraving of piezoelectric materials for radiofrequency devices (Quartz, etc.)

The development of these processes has received financial support from the Region Bourgogne Franche-Comté.

contact : florent.bassignot@femto-engineering.fr

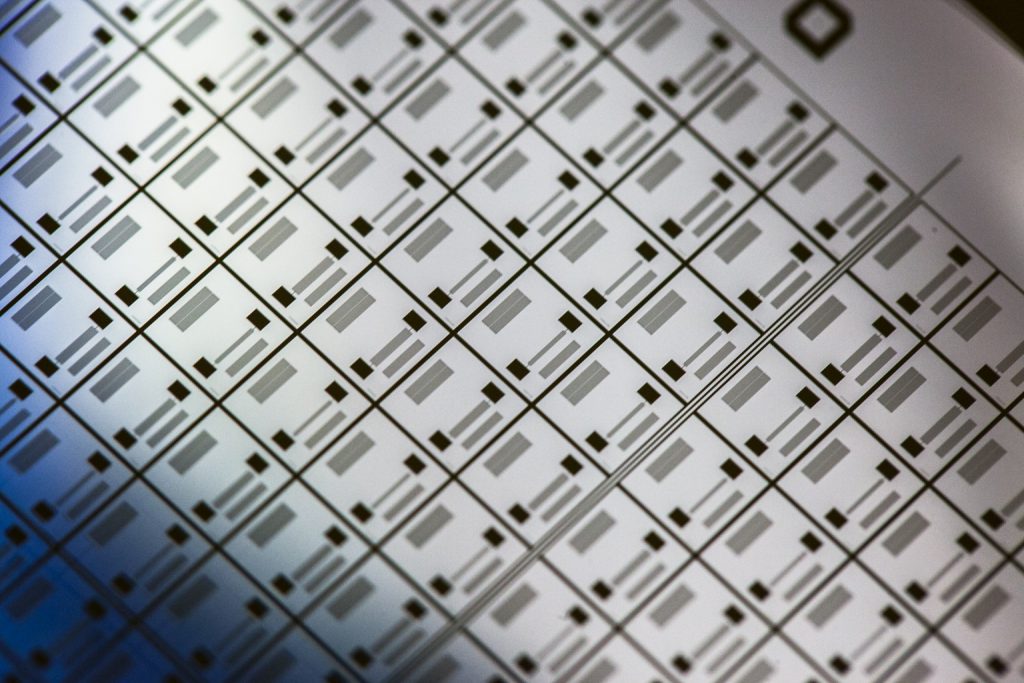

UV & electronic lithography Photolithography mask manufacturing

Deposition of thin and thick layers

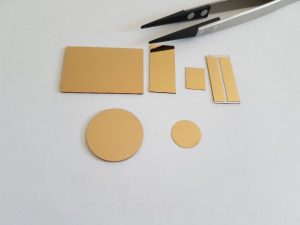

Precision cutting Lapping & polishing Wire bonding Wafer bonding Micro-assembly (flip-chip)

Microscope (MEB, optic, FIB), mechanical profilometer Specific measures : material constraints, optical index, contact angle

Femto Engineering | From science to society

15B avenue des Montboucons, 25030 Besançon Cedex – France

Subscribe to our newsletter to receive all our news directly